Peter Walcott is a long time businessman and headwear designer from Australia with over forty years of experience in the Australian hat industry.

Based in West Gosford, ooGee Australia is an attempt by Walcott to reinvigorate local manufacturing and ensure the future of traditional hat-making in Australia. OoGee Australia celebrates native styles while bringing in Walcott’s own Flexibraid® technology to create lightweight, durable, and stylish hats.

Lily Shaw chats to Peter Walcott about how ooGee Australia is changing the game for Australian headwear.

Can you tell us a bit about how you first started ooGee Australia?

I fell into the headwear industry in 1979 when I was only 19 and soon found that I had a knack for designing and sales. Unfortunately, most of the Australian hat-making industry struggled to compete with imported headwear when tariffs were restructured in the 1980’s. When the pandemic hit in 2019, I did become quite concerned what lay ahead for the company. While pondering what the future held, I remembered an old saying “change before you have to “So, I thought, what greater time than now to get back into manufacturing. Especially now while the growing groundswell across the country was to source local.

Though they were scary times in so many ways, I felt it was the right time to take the bull by the horns and set up a factory at my West Gosford facility. To do so was a multi-stage process. Significant machinery needed to be sourced from overseas as there are several critical processes that go into constructing a piece of headwear. We then reached out to the local community to find factory staff with the inherent skills to support the production. To our delight, word of mouth through the Central Coast community delivered a skilled and happy team who have embraced the specific techniques we required.

Who or what are some of your biggest inspirations when designing your headwear collection?

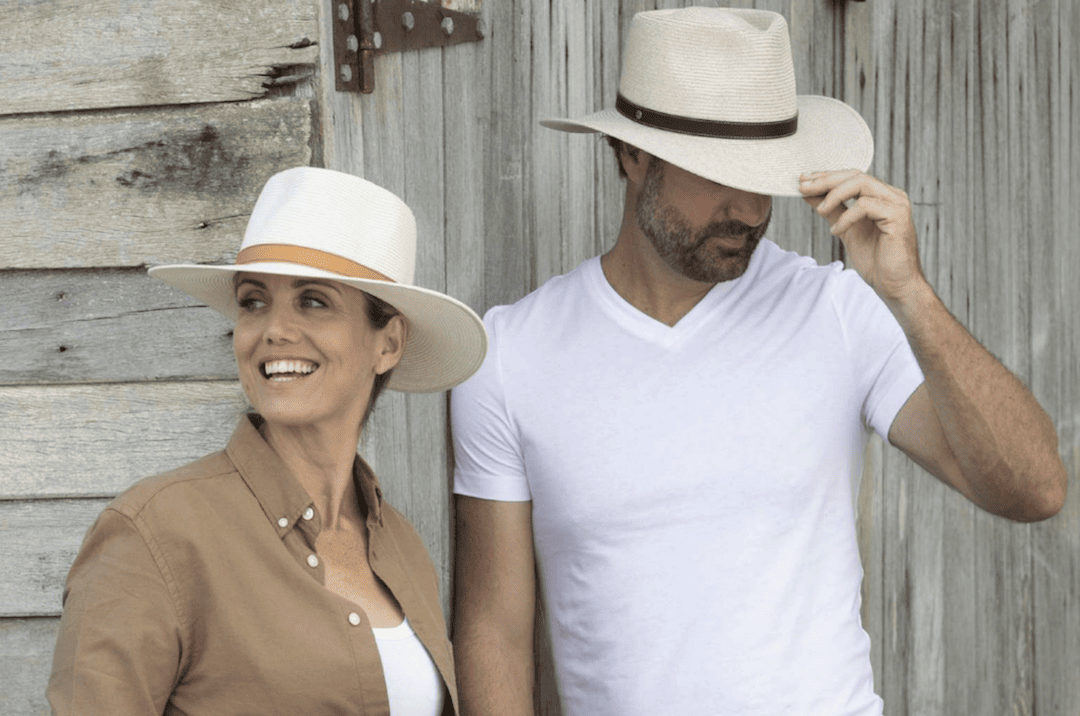

As a kid I did love the old westerns and especially the movie “The Man from Snowy River”. So, whereas we gave a nod to traditional “country” shapes, we wanted ooGee to offer an alternative to the hats normally associated with the bush ; felt and leather styles which, although tough, are inherently hot to wear in the typical hot Australian climate. With that thinking we created styles that are lightweight, cooler and provide UPF50+ sun protection. We also wanted ooGee to reflect an urban edge, a hat that was cool to wear and practical to travel with – a hat for the Bush, Beach and Beyond. We wanted the range to reflect our immense natural outdoors so what better way than to name each style after an iconic Australian waterway.

Tell us about your Flexibraid® technology. How does it stand out from other materials and textile processes?

Claims are routinely made that hats are “crushable” or “travel-friendly” but we are yet to find a material that compares to our proprietary Flexibraid®. This is a technology that was years in the making. I worked with my technicians experimenting with dozens of different yarn and filament combinations, looking for a braid with a natural handle which retained a “memory” when flat packed. The result became Flexibraid which is lightweight, breathable and highly resilient to being crushed – the material which has become the gold-standard fortravel hats.

What is the process for creating an ooGee hat?

Without divulging all my manufacturing secrets, the ooGee hat starts as a raw “hood” which has been created by the circular, hand-sewing of the Flexibraid strands into a basic, shapeless cone. This hood can be then formed into a variety of hat shapes with each shape requiring a specific heat and pressure-generated block. By applying pressure at a required temperature for a specific time the general hat shape is formed. Sometimes moisture needs to be applied – each hat style requires a unique “recipe”.

Inserted into the edge of the brim is a high-quality wire. The choice of wire serves to either maintain the brim to a specific shape or to allow the brim to be reshaped to a style desired by the wearer. In our sewing room, we add the internal headband, inserting the ComfyFit size-adjustor. Most leather trims are sourced locally and hand cut to decorate the crown. Labelling, tagging and final inspection is completed before the ooGee hat is ready to send.

Why is buying local, ‘Australian-made’ products so important?

Ultimately, supporting Australian manufacturing is about jobs and the knock-on effect to other businesses around it. The value-add effect and the benefit to the local economy is critical, as many other businesses are also suppliers into Rigon’s local facility. Wherever it can, Rigon sources as much as possible locally, for its Australian made product. In addition to producing core ranges, the lead-time benefits and manufacturing flexibility, allows Rigon to develop and deliver short run bespoke headwear styles as well.

How are you preserving the art of traditional hat-making in Australia?

One needs to make a distinction between millinery and commercial hat-making. While there is ever a Melbourne Cup, there will always be niche, bespoke, Australian millinery. What Rigon has rejuvenated is the broader industry of hat-making in Australia where commercial quantities of headwear can be produced locally, providing jobs for skilled sewers and general machinists. It is ironic that in the 1980’s, we shipped our Australian machinery to our factory overseas and trained overseas staff the techniques we used to produce hats here. Now we have come the full circle, importing machinery into Australia and retraining Australians in the techniques of commercial hat-making.

Are there any upcoming plans for the brand you’re especially excited for?

Already we have received interest in the ooGee brand from Europe and the USA. The range is unlike anything currently available overseas and being Australian made has enormous appeal.

Do you have a favourite ooGee hat design?

We have tried to make ooGee as gender neutral as possible. It is hard to go past the Hunter Creek; a hat which encapsulates a classic Aussie shape, provides fantastic sun protection and is available in 5 colours. The Hunter Creek is the signature shape around which the entire ooGee range is built.

How have the ooGee hats been received so far?

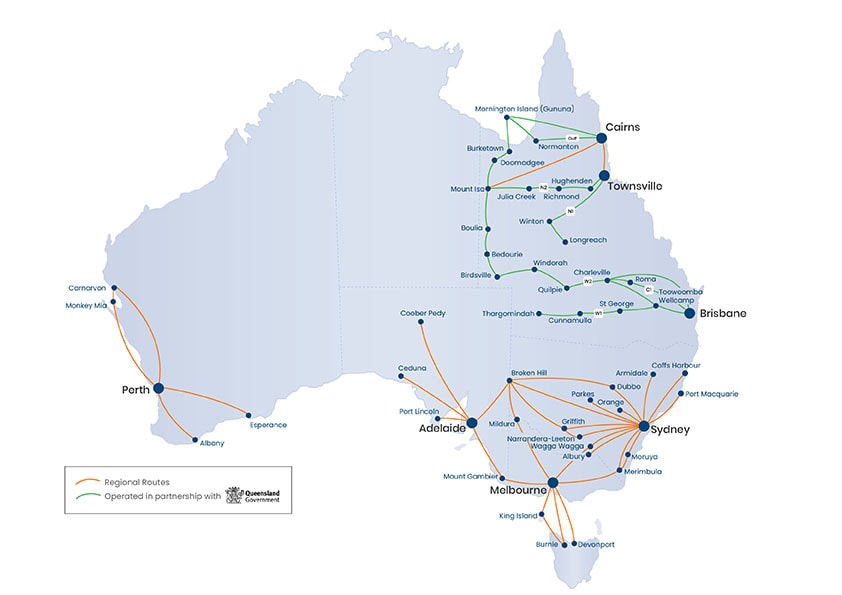

OoGee entered the market about 12 months ago with a soft launch, allowing us to gauge the demand and to get our supply chain system, well-oiled. With virtually no promotion, we were delighted with the response, quickly being secured as a supplier nation-wide by the Horseland group. For Horseland, ooGee filled a fresh, practical niche against the heavy felt hats they traditionally carry. Other independent saddleries and boutiques across the country have already become ooGee stockists. As a new kid on the block, the response has been excellent.

Check in with Miranda Tapsell or Jimmy Barnes on our Aussie Stars page!